查看更多

银河至尊登录地址就业

recruitment

滚球直播进入国家“双一流”建设行列重点建设“能源电力科学与工程”学科群

查看更多

专题网站

special subject

-

一线 | 金牌课堂:罗贤缙《C++程序设计》,让学生做课堂的主角

一线 | 金牌课堂:罗贤缙《C++程序设计》,让学生做课堂的主角 -

金沙艺游场9159与你,平分秋色

金沙艺游场9159与你,平分秋色 -

一线 | 分层施教:《物理实验》教学团队点亮学生科技创新的奋进之路

一线 | 分层施教:《物理实验》教学团队点亮学生科技创新的奋进之路 -

“基层就业卓越奖”,金沙艺游场9159+1!

“基层就业卓越奖”,金沙艺游场9159+1! -

明日开幕!让我们携手共赴金沙艺游场9159新征程

明日开幕!让我们携手共赴金沙艺游场9159新征程 -

一线 | 校园守护者张红梅:勺舀烟火,盘盛关爱

一线 | 校园守护者张红梅:勺舀烟火,盘盛关爱 -

一线 | 环境科学与工程系碧空环保团队:用青春的力量守护蓝天白云

一线 | 环境科学与工程系碧空环保团队:用青春的力量守护蓝天白云 -

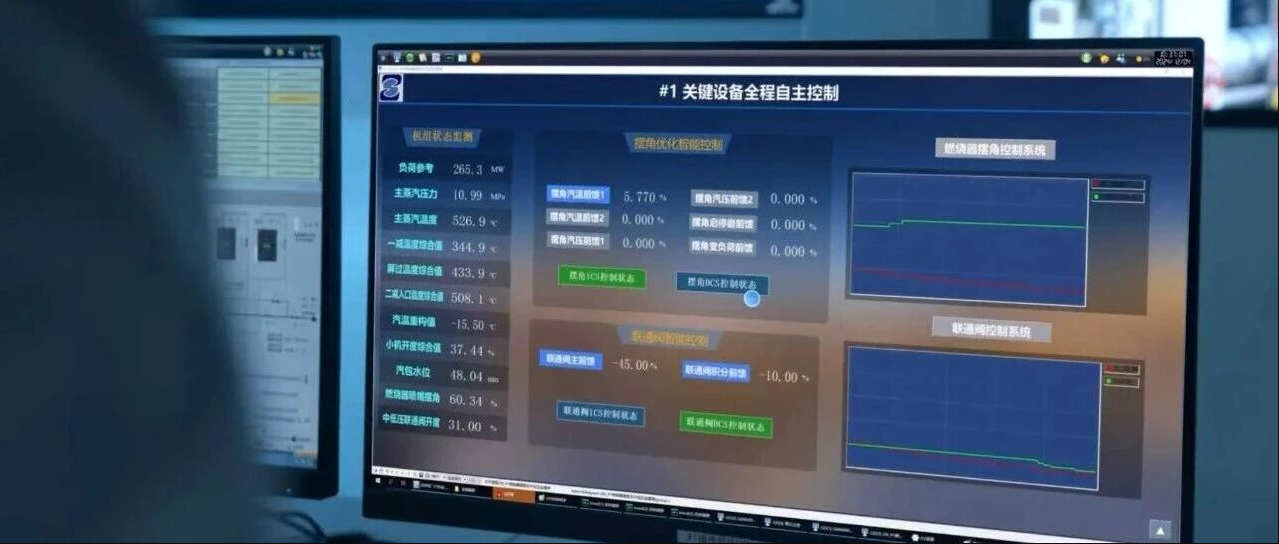

走进新能源电力系统全国重点实验室| 按下智能发电“加速键”

走进新能源电力系统全国重点实验室| 按下智能发电“加速键” -

一线 | 自动化系用一张文明公约点亮宿舍生活

一线 | 自动化系用一张文明公约点亮宿舍生活

-

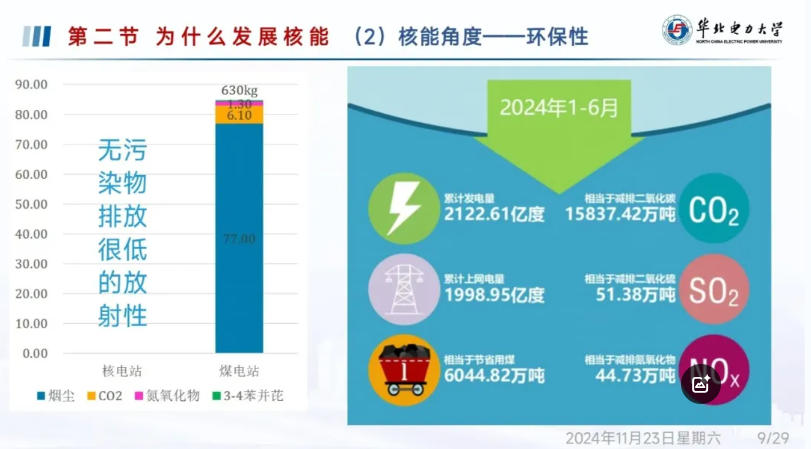

一线 | 《能动强国》,催人奋进

一线 | 《能动强国》,催人奋进 -

燃爆金沙艺游场9159!能源电力企业天团现场揽才~

燃爆金沙艺游场9159!能源电力企业天团现场揽才~ -

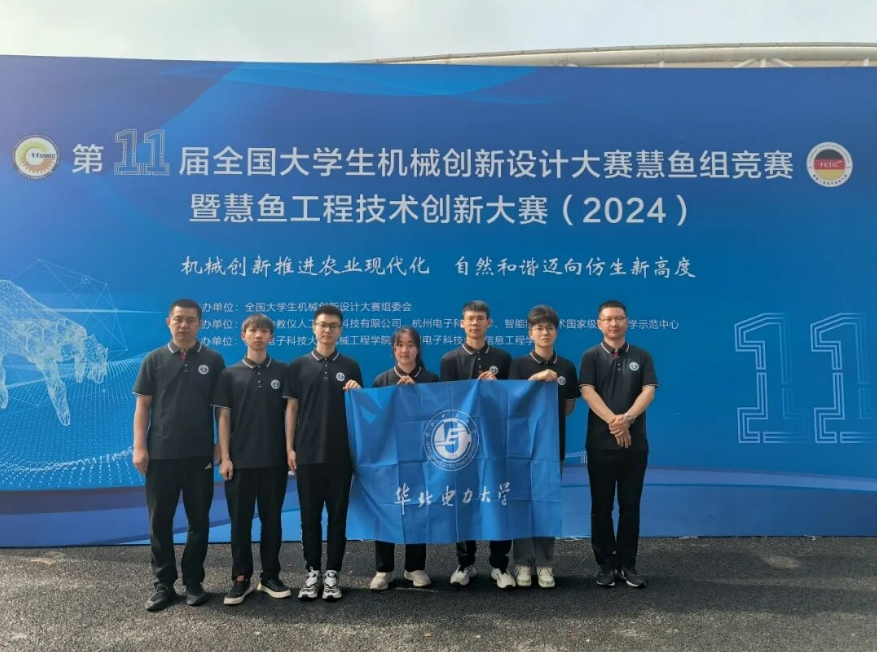

一线 | 全国大学生机械创新设计大赛一等奖,加冕荣光!

一线 | 全国大学生机械创新设计大赛一等奖,加冕荣光! -

一线│优化与稳定并重 点亮能源电力科技研究新方向——访电力工程系多能源系统优化与稳定技术研究团队

一线│优化与稳定并重 点亮能源电力科技研究新方向——访电力工程系多能源系统优化与稳定技术研究团队 -

67岁!亲爱的金沙艺游场9159,生日快乐!

67岁!亲爱的金沙艺游场9159,生日快乐! -

67 载时光里,念念不忘是金沙艺游场9159

67 载时光里,念念不忘是金沙艺游场9159 -

重阳承敬意! 金沙艺游场9159携手老同志共绘温馨画卷

重阳承敬意! 金沙艺游场9159携手老同志共绘温馨画卷 -

让青春与迷彩来一场同频共振!

让青春与迷彩来一场同频共振! -

颜值与美味双在线!金沙艺游场9159专属月饼精彩亮相

颜值与美味双在线!金沙艺游场9159专属月饼精彩亮相